Custom pcb board manufacturer China pcb manufacturing

Custom pcb board manufacturer China pcb manufacturing

FASTPCBA is a high-tech enterprise in Shenzhen custom pcb board manufacturer. Under the attention and support of the fenghuangSatellite TV, after the manufacturingof the Longxin No. 3 circuit board, the company has become more aware of the positioning of precision PCB manufacturing. In the harsh market competition, it hasbeen leading high-end industriesfordecadesin automotive electronics, medical, aviation, military applications, industrial automation, smart home etc.

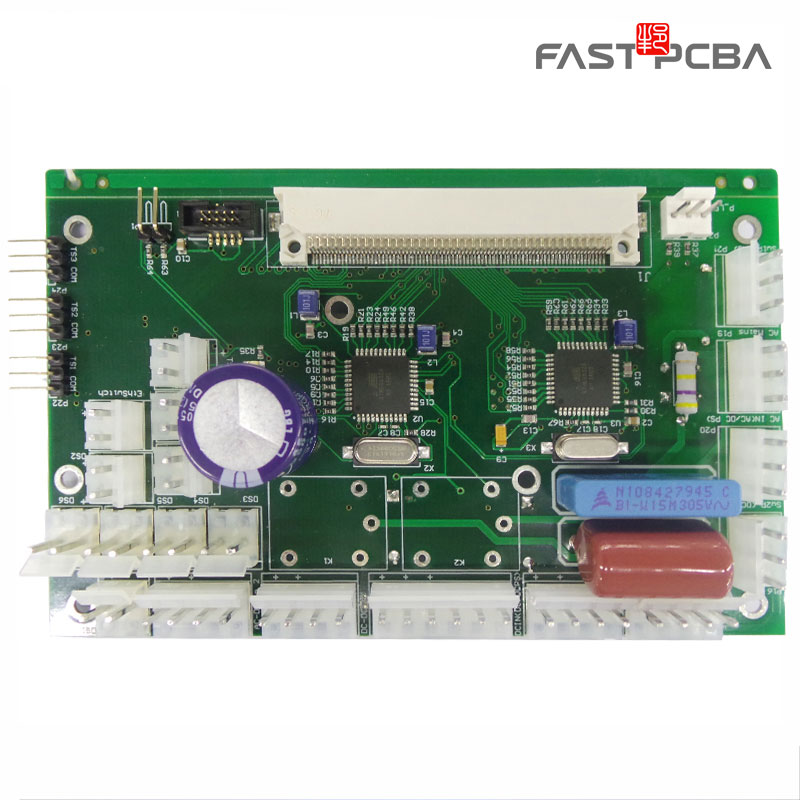

The following low noise air pump custom pcb board manufacturing is one of our examples in the smart home industry.

Instructions:

When removing the instrument from the box, please check if the accessories and warranty card are complete.

Check the appearance of the instrument and whether there are any abnormal phenomena such as serious damage caused by transportation.

Preparation and connection before starting:

(1) Replace the seal plug on the “Air Input” port on the rear panel of the instrument with the “Filter” in the accessory.

(2) Tighten the seal female on the “air output” port on the rear panel without air leakage.

(3) Ground the instrument power cable ground (middle piece) and the chassis.

(4) Turn on the power, start the switch, and the instrument starts working.

(5) During the process of starting and closing the compressor, the compressor will automatically discharge some water every time it stops working, but it cannot completely replace the manual drainage, so it is still necessary to drain manually.

(6) After the above is normal, turn off the power, remove the pressure cap on the air outlet, connect the instrument with the outer diameter pipe and ensure that the seal does not leak.

(7) When you work again, just turn on the power switch.

(8) If only one output is used, the other outlet can be sealed with a blind mother.

Precautions:

1.Because the compressor is an inductive load, the instantaneous current several times higher than that during normal operationwhen the power is turned off . It is easier to fuse and the 8A fuse should be used.

2. The compressor does not start during the working process, and the thermal protection relay starts, indicating that the compressor temperature is too high, and it will automatically return to normal after cooling.

3. In order to avoid excessive water in the machine and affect the purity of the air, you need to press the drain switch for a few seconds before shutting down.

4. When viewing the color-changing silica gel from the observation window, the user can replace the new silica gel or dry it as needed.

5. In order to ensure the purity of the gas, the instrument needs to replace the activated carbon once every 1000 hours of operation.

6. Since the compressor is in the open working mode, the lubricating oil will be discharged out of the machine with water, causing consumption. Therefore, the compressor should be properly lubricated after one year of use.

7. The inlet filter should be cleaned regularly to keep the intake air unobstructed. Otherwise, the compressor workload will increase and heat. If the temperature is too high, overheating will occur and the machine will stop.

FASTPCBA provides customers with custom pcb board manufacturing and assembly services for 15 years, has a stable and reliable procurement channel for components, and has its own PCB manufacturing plant; welcome to consult:pcba23@pcb-smt.net