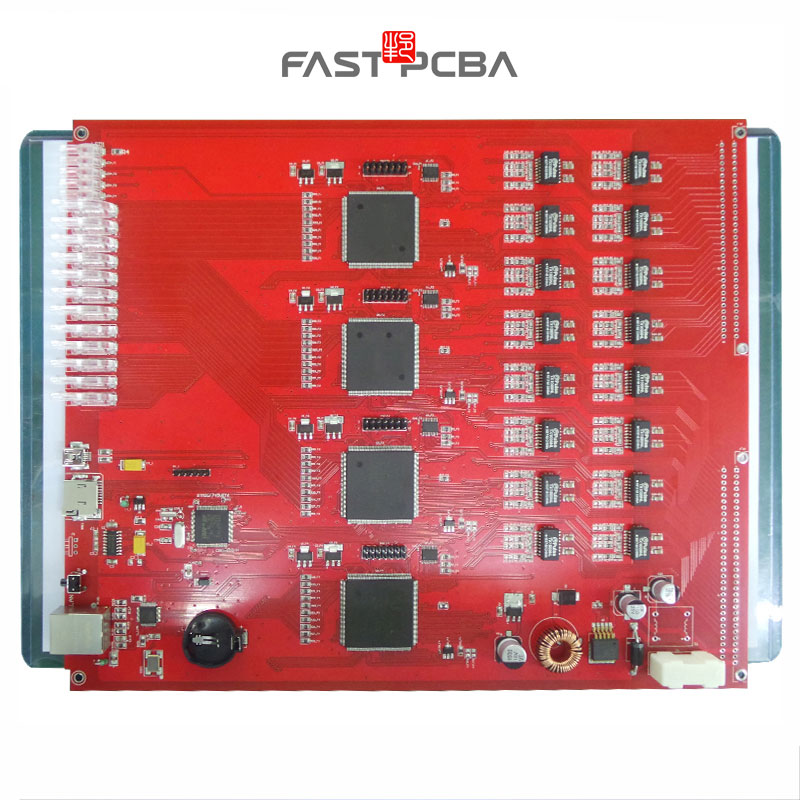

SMT circuit board assembly for industrial vision control systems

SMT circuit board assembly for industrial vision control systems

Application

Industrial vision systems can be used for a wide variety of tasks. According to the usage, the following examples can be cited: target positioning, orientation and identification in CIDMAC; defect inspection (such as cracking of metal components); sorting (such as picking nuts from the husk); grading (such as calculating the rate of fatness and thinness of meat) Determination of the liquid level in the bottle or tank; online measurement of the size of food, cloth or machined parts; inspection of the correctness of components; inspection of food, cosmetics, pharmaceutical contamination; detection of chemical leakage; instrument calibration; tool wear detection and product packaging inspection. The industrial vision system can be roughly divided into three categories: automatic inspection, component processing and assembly, and production process control according to the characteristics and complexity of the measured objects and the specific tasks to be processed.